4 Process Optimization and Management for Evolving Site Conditions

4.1 Introduction

This section describes optimization of a P&T system during different steps of site remediation. The information in this section provides ideas and tools to use when developing recommendations for anyone conducting an optimization review, regardless of the scale of the optimization.

Optimization Life Cycle Navigation Diagram

Source: E. Madden, ITRC. Used with Permission.

4.1.1 Importance of Optimization of Operation and Maintenance in Pump and Treat Systems

As previously stated, optimization should be included as part of the site characterization, design, and O&M program. The goal of a P&T system is to achieve a desired effect or condition in the subsurface rather than to maintain a specific flow through a treatment plant or to attain specific discharge criteria. The O&M of the system components, both belowground and aboveground, are meant to achieve this in a reliable and cost-effective manner. These operations have to be tailored to a changing set of site conditions (usually subsurface). Those responsible for O&M must keep the goal in mind and be creatively flexible to adapt to changes. Periodic optimization of the system can help facilitate this flexibility and adaptability. This section focuses on the optimization recommendations that may address the components identified in Figure 4‑1.

Source: ( USEPA 2022[AZTQDXPW] USEPA. 2022. “Optimizing Site Cleanups.” https://clu-in.org/Optimization/index.cfm. ).

4.1.2 Goals of Optimization

The recommendations developed during the optimization of any groundwater remedy should represent a balance of all factors that affect overall effectiveness, including performance, protectiveness, and cost. Emphasizing only cost-reduction aspects misses an opportunity to consider the best value for the funds spent to meet the defined remedial objectives. This best value is a near-optimal trade-off between cost and achieving the protection of potential receptors and improvement of the environment as required. Reducing costs too much may jeopardize compliance and protectiveness. In some cases, the optimization processes will result in a remedy that is both more protective and less costly. The best optimization should be holistic and consider all aspects of the remedy.

|

Optimization recommendations should address the following:

|

The effectiveness of the remedy should include its ability to achieve its remedial action or corrective action objectives to protect human health and the environment. The cost evaluation for any recommendation considers the simple cost impacts of changes, of various levels of complexity, and may consider the more difficult question of the benefits of changes to the remedy now for shortened cleanup duration and avoided future costs. Recommendations for acceleration of the remedy, to the extent practical, often can translate into reductions of life cycle costs and can remove future potential liabilities as site conditions change. The economic analysis of remedy acceleration also depends on the discount rate assumed for future remedial expenses, and this is often related to the rate of return for alternative uses of the funds. Even if site equipment and infrastructure are functional and maintenance costs are not high, optimization analysis of maintenance practices may result in recommendations for preventative maintenance that would avoid future repair costs and performance upsets that would represent unacceptable risks. Finally, the optimization evaluation is an excellent vehicle to recommend ways to make the remedy “greener” and to make the remedy more robust with regard to environmental changes such as a warming climate.

Recommendations for optimization may address poor protectiveness; failure of certain components; high costs for energy, labor, or materials; changing site conditions; or other specific factors. It may also focus on how to reduce groundwater concentrations at the site to levels below applicable MCLs or other applicable remediation goals in the most cost-effective and temporally effective manner. This section identifies common considerations that should be addressed when developing recommendations during an optimization study of a P&T remedy, as guided by the performance evaluation described in Section 3.

The categories of recommendations include the following:

- changing the CSM

- optimizing the existing system, including well locations and maintenance, O&M of the conveyance and treatment system, and the monitoring program

- enhancing the P&T system, including supplementing P&T with other in situ technologies, applying land-use controls, and transitioning to MNA (preview of Section 5)

The section also discusses the considerations for estimating the costs for the recommendations and approaches to implementing the recommendations.

4.2 Recommendations to Address Changes to the Conceptual Site Model

The CSM (see Sections 3.1.3 and 3.2) should be updated (if it has not been recently updated) based on new information from the optimization evaluation. It is important to understand changes in site conditions such as newly detected contaminants, variances in the expected concentrations of known contaminants, changes in the movement (direction and/or rate) of contamination, and contaminant distribution, among other characteristics. This type of information should be incorporated into the development of recommendations for the optimization of P&T systems.

4.2.1 Role of Advanced Site Characterization in the Optimization of Pump and Treat

As discussed in the ITRC guidance on Implementing Advanced Site Characterization Tools ( ITRC 2019[ZMM54HEL] ITRC. 2019. “Implementing Advanced Site Characterization Tools.” Washington, D.C.: Interstate Technology & Regulatory Council, Implementing Advanced Site Characterization Tools Team. https://asct-1.itrcweb.org/. ), advanced site characterization is a necessary step for the proper design, implementation, and optimization of a P&T system and will lead to an updated CSM. Since many existing P&T systems were constructed before advanced site characterization tools (ASCT) were available but do not have an anticipated end date for site closure, additional investigations using ASCT will likely save funds over the life of the project. As such, optimization recommendations will often suggest additional high-resolution site characterization (HRSC), and this can support recommendations for revisions to the pumping scheme or recommendations for supplemental remedial technologies to address specific areas (e.g., high concentration source areas). The recommendations may include the use of near-real-time analysis techniques (e.g., the “Triad” approach)

| P&T optimization can be improved through enhanced understanding of site conditions. |

Those conducting the optimization and developing recommendations should provide their rationale for recommendations of additional site characterization. Pockets of contamination or preferred contaminant pathways may be undetected through conventional site characterization methods and may affect the progress of cleanup. Thin high-permeability layers can represent significant contaminant pathways that affect plume paths and capture. Direct sensing technologies may provide information on the presence and level of volatile organic compounds (VOCs) or detect the presence of NAPLs, allowing for targeted selection of the locations of extraction wells. Detection and delineation of degradation products created during the transformation of contaminants in the subsurface can be improved with the use of ASCT. Borehole and surface geophysics can be used to infer preferential groundwater flow paths, direction, and velocity, which can be used to determine locations and pump selection to maintain hydraulic capture at a site.

ITRC has previously published guidance on selecting Advanced Site Characterization Tools. Many of the concepts are also addressed in the ITRC guidance on Characterization and Remediation of Fractured Rock, Optimizing Injection Strategies and In situ Remediation Performance, and Integrated DNAPL Site Characterization and Tool Selection.

4.2.2 Changes in Plume Contaminants

Changes in the understanding of the plume contaminants can affect the efficacy of a P&T system and drive the recommendations to improve the system. P&T systems are designed to remediate a particular set of contaminants down to a particular concentration. The need to address additional contaminants or exceedances of discharge criteria can arise due to the following issues:

- incomplete site characterization

- increased or decreased pumping rates that result in changes to the effectiveness of the treatment system

- new or emerging contaminants identified during updates to the CSM

- unexpected treatment by-products

- changes in regulatory criteria (see Section 7.3)

One optimization recommendation may be to minimize the spatial extent of the influence of the P&T system to reduce movement of an adjacent plume into wells of the P&T system. This may involve adjustment of pumping rates at individual wells or cyclic operation of the wells to reduce the area of influence of individual wells.

Changes in regulatory criteria can include changes in the maximum contaminant level, reduction of the discharge limit of an existing contaminant, or new criteria for CECs, as discussed in Section 7.3. Recommendations for changes to the treatment and extraction systems may be made to address this.

After identification, assessment, and integration of the additional contaminants within the CSM (see Section 3), development of an implementation strategy will depend on site-specific factors, the physical and chemical properties of the additional contaminants to be targeted, and remedial objectives. The following recommendations have been developed for the implementation of a remediation strategy for any additional contaminant after the CSM has been updated:

- Review applicable ITRC and regulatory agency guidance on the additional contaminant (e.g., ITRC Technical Resources for Addressing Releases of 1,4-Dioxane, ITRC Technical Resources for Addressing Environmental Releases of Per- and Polyfluoroalkyl Substances).

- Determine whether the additional contaminant is present in the effluent or has been removed or destroyed by the existing P&T system (see Section 7.3).

- If the system destroys the additional contaminant, recommend determining whether any daughter products of concern are in the effluent and determine treatment requirements for the daughter products, if present.

- If the additional contaminant is removed from the P&T system by an interim process (e.g., precipitation or adsorption), recommend determining the process for removing the chemical. The media would then need to be sampled to determine whether it falls within any current regulatory threshold, and requirements for proper management of the media (further treatment or proper disposal) should be determined.

- If the additional contaminant is present in the effluent, recommend a means of either removing or destroying the CEC. The addition of any process to a P&T system will need to be reviewed by local, state, or federal agencies before the P&T system can be modified.

- If possible, recommend a means of source area remediation that could potentially be used to reduce the impact of the additional contaminant on the P&T system. The application of any source area remediation would require review by local, state, and federal agencies.

As an example, per-and polyfluoroalkyl substances (PFAS) are a family of contaminants identified by the USEPA for which applicable federal MCLs are currently evolving. “[A] growing body of scientific evidence shows that exposure at certain levels to specific PFAS can adversely impact human health and other living things” ( USEPA 2021[WJUY2HAN] USEPA. 2021. “PFAS Strategic Roadmap: EPA’s Commitments to Action 2021—2024,” October, 26. https://www.epa.gov/pfas/pfas-strategic-roadmap-epas-commitments-action-2021-2024. ). USEPA seeks to “accelerate the deployment of treatment, remediation, destruction, disposal, and mitigation technologies for PFAS, and ensure that disposal and destruction activities do not create new pollution problems…” ( USEPA 2021[WJUY2HAN] USEPA. 2021. “PFAS Strategic Roadmap: EPA’s Commitments to Action 2021—2024,” October, 26. https://www.epa.gov/pfas/pfas-strategic-roadmap-epas-commitments-action-2021-2024. ). Many P&T systems are currently being assessed for PFAS. If present at levels of concern, PFAS may be remediated with a P&T system using adsorption with GAC or ion exchange. If GAC is part of the existing remedy and PFAS is found, a recommendation to reevaluate the frequency of change out of carbon may be needed. If past operations suggest the potential presence of PFAS and no evaluation has been done, the optimization team may recommend limited sampling to confirm the presence or absence of these compounds. ITRC has issued documents on PFAS ( ITRC 2022[FNZQLJRW] ITRC. 2022. “PFAS Technical and Regulatory Guidance Document and Fact Sheets.” Washington D.C.: Interstate Technology & Regulatory Council, PFAS Team. https://pfas-1.itrcweb.org/. ) including the PFAS Technical and Regulatory Guidance Document, PFAS fact sheets and explainer videos, training module videos, and external tables of data. There is also guidance from ITRC on 1,4-dioxane ( USEPA 2021[WJUY2HAN] USEPA. 2021. “PFAS Strategic Roadmap: EPA’s Commitments to Action 2021—2024,” October, 26. https://www.epa.gov/pfas/pfas-strategic-roadmap-epas-commitments-action-2021-2024. ), and ITRC is also developing guidance on implementation of remediation of microplastics ( ITRC 2023[GFVIWWM6] ITRC. 2023. “Microplastics.” Washington, D.C.: Interstate Technology & Regulatory Council, MP Team. https://mp-1.itrcweb.org. ).

4.2.3 Optimization under Changing Groundwater Flow Conditions

Changes in site conditions can contribute to changes in groundwater flow directions and velocity over time. Changes in recharge at a site can be caused by variations in precipitation, redevelopment and associated modifications to stormwater management, impervious/pervious cover or pavers, drainage features, surface-water flow patterns, and climate change. The influence from pumping wells withdrawing groundwater in the vicinity of a site can create changes in groundwater flow conditions. Any optimization recommendations should consider the specific conditions at the site, and specific recommendations should be made to improve the resiliency of the system (see Section 6).

A long- or short-term increase in water levels may also affect the recommendations for the P&T system. In an unconfined aquifer, increasing water levels may change the aquifer transmissivity and vertical location of the plume relative to the extraction well screens such that vertical containment is compromised. This may require recommendations to increase pumping rates or alter setting of the pump intakes. If the rise of the piezometric surface changes horizontal and vertical hydraulic gradients, recommendations for changes to the pumping rates and well locations may be necessary. The characteristics of the adjacent and overlying hydrostratigraphic units—whether perched, leaky-confined, or confined aquifers; a natural aquitard; or anthropogenic drainage controls—may be a consideration for optimization modifications if these changes in potentiometric levels alter flow and contribution of groundwater to the system. Any of these units with varying transmissive or storage properties may be a source of antagonistic water chemistry or natural microbial activity that could adversely impact operations. An aquitard that was, prior to these water level changes, in equilibrium with normal operations may have increased leakage from an overlying shallow aquifer into the target aquifer. These sources may contribute undesirable changes in water chemistry, alter the capture zone, or exacerbate microbial activity that might impact aquifer intercept efficiency, affect the pumps, or spread into conveyance piping and treatment system operation if not considered as part of the optimization effort.

Drought conditions result in a decline of groundwater levels over time. Projected impacts of climate change may include decreases in aquifer recharge that lead to water level declines. Long-term pumping, if reinjection or basin/gallery recharge has not been implemented, will exacerbate the decline. Declining water levels in an unconfined aquifer will reduce the transmissivity, thus affecting pumping rates and capacity. The optimization recommendations should consider the long-term trends in water level impacts to assure goals are met. LNAPL, if present, could be mobilized, and dissolved concentrations of LNAPL contaminants could increase. Recommendations from the optimization may include reductions in pumping rates (associated with a decreased thickness of the saturated zone to support pumping) or the addition of extraction wells pumping at lower rates to maintain capture.

Any current or proposed activities that may involve changes in aquifer stress should be incorporated into the optimization of the P&T system. Recommendations should be provided to mitigate these changes. Installation of new recovery wells (such as groundwater remediation, irrigation, or water supply wells in the vicinity) or dewatering wells for construction purposes that withdraw groundwater from the same aquifer may cause changes in groundwater flow conditions and may require changes to the optimization plans. Similarly, increases or decreases in pumping rates of existing nearby wells withdrawing groundwater from the aquifer could also create the need for changes. New areas of ponded water (such as depressions collecting surface-water runoff, engineered recharge facilities, seasonal irrigation ditches, ponds created by beavers, or other blockages in natural drainageways) may create areas of induced recharge to the pumping wells that should be considered in the optimization.

4.2.4 Change in Regulatory Standard

The operation of P&T systems may need to be changed to meet updated regulatory standards. Examples include CECs; changes in discharge limitations, Regional Screening Levels, or MCLs; new or revised reporting or monitoring requirements; etc. Most changes involve deadlines to achieve compliance with technical and or regulatory time frames established in the enabling statutes or regulations. These changes can be triggers, or be opportunities, for optimization recommendations. See Section 7.3 for more detail.

4.3 Optimizing the Existing System

Once the P&T system performance evaluation is completed (see Section 3), the results of the evaluation can be used to develop recommendations for system optimization. Optimization should focus on adjusting the operation of the P&T system or incorporating changes in system components to improve performance and accelerate progress toward meeting remedial objectives to the extent practical.

This section discusses different aspects of system optimization that can improve the effectiveness of a P&T system.

|

Optimization may include the following:

|

4.3.1 Extraction System

4.3.1.1 Adjustments to Pumping and Injection Rates and Locations

A key optimization consideration for P&T systems is refinement of the extraction (and injection, if used) strategy. This aspect directly relates to the ability to attain containment and/or cleanup goals and impacts treatment costs. The optimization should consider the following four scenarios:

- The current system is not achieving its goals of cost-effectively containing and/or cleaning up the plume. Recommendations would focus on improving performance and/or improving the CSM (e.g., by further characterization of the source area).

- The current system is pumping more water than necessary to meet its goals. Recommendations would focus on what amount of reduction in pumping would be appropriate, what wells to remove from the pumping scheme, and whether to relocate extraction wells that withdraw less water.

- The current acceptably functioning system could be enhanced to achieve its restoration goals more quickly. Recommendations would focus on alternative pumping and injection locations that would increase throughput/flushing. Targeted in situ treatment of source area(s) or hot spots may also be recommended.

- The system capacity may need to be enhanced and resiliency increased to accommodate expected climate changes (see Section 6). Recommendations would address further pumping and treatment capacity, need for deepening extraction and monitoring wells, etc.

Although these goals are for existing systems, the same considerations would apply to systems in various stages of design.

As discussed in Section 3.3, the adequacy of containment should be assessed through a multiple-lines-of-evidence approach, such as the approach laid out in the USEPA capture zone guidance ( USEPA 2008[7ILB4T4V] USEPA. 2008. A Systematic Approach for Evaluation of Capture Zones at Pump and Treat Systems. Ada, OK: U.S. Environmental Protection Agency, National Risk Management Research Laboratory. https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=187788. ). The analysis may involve inspection of piezometric surface maps, simple calculations, evaluation of chemical trends in nearby monitoring wells, or numerical simulation/modeling. If containment is found to be insufficient, either pumping from existing wells should be increased or new wells should be added. If more extraction is occurring than necessary to meet objectives, reduced pumping can be proposed at specific locations. This can reduce both costs and energy use. Again, modeling by the optimization team, the project team, or a third party may be helpful. See Section 4.3.1.3 on modeling optimization.

Where cleanup is a goal (rather than containment), the optimization team may recommend reductions in pumping from extraction wells that remove small amounts of mass (provided the pumping is not necessary to maintain plume control) to focus on treatment capacity for wells that contribute a higher amount of mass.

In some cases, such as permeable aquifers, both containment and cleanup goals can be met more efficiently through paired extraction and injection. For cleanup, the injection of clean treated water upgradient of the plume with extraction within or downgradient of the plume can result in more rapid flushing, enhanced back diffusion, and delivery of amendments (if part of the remedy or optimization-recommended enhancements—see ITRC’s Optimizing Injection Strategies and In situ Remediation Performance guidance document ( ITRC 2020[SKNUVGR8] ITRC. 2020. “Optimizing Injection Strategies and In Situ Remediation Performance.” Washington, D.C.: Interstate Technology & Regulatory Council, OIS-ISRP Team. https://ois-isrp-1.itrcweb.org/. )). Injection downgradient of containment extraction wells can enhance the effectiveness of capture. Injection of treated water can also help maintain the saturated thickness and productivity of an unconfined contaminated aquifer.

The three-dimensional effects of extraction and injection must be considered when developing optimization recommendations. Long screens on extraction wells may draw water from both thin contaminated and relatively clean strata, increasing treatment volumes and diluting the influent. Although higher extraction rates may need to be sustained to maintain capture, a focus on the vertical intervals, defined by HRSC, that conduct the plume may be an important recommendation. Extraction from a deeper contaminated zone or injection into a shallow contaminated zone may drive more contamination across an aquitard into the deeper zone. Where vertical migration of contaminants may be occurring, such as through imperfections in an underlying aquitard or an improperly constructed well, injection of clean water into the deeper aquifer may reverse hydraulic gradients and mitigate or block that contaminant transport route.

The optimization of NAPL recovery can be challenging. The recommendations may include using a more aggressive technology (e.g., MPE), refining the targeted vertical interval for extraction where NAPL saturation is highest, testing NAPL transmissivity to assess NAPL recoverability, and using seasonal extraction during a time of lower water table (for LNAPL). ITRC documents provide information relevant to the development of such recommendations. These include guidance on LNAPLs ( ITRC 2018[SMJT9P55] ITRC. 2018. “Light Non-Aqueous Phase Liquid (LNAPL) Site Management: LCSM Evolution, Decision Process, and Remedial Technologies.” Washington D.C.: Interstate Technology & Regulatory Council, LNAPL Update Team. https://lnapl-3.itrcweb.org/. ) and DNAPLs ( ITRC 2020[JWKDF22N] ITRC. 2020. “Integrated DNAPL Site Strategy.” Washington D.C.: Interstate Technology & Regulatory Council, IDSS Team. https://idss-2.itrcweb.org/. ).

4.3.1.2 Coordinated Injection and Extraction

The ability to achieve a specific reduction in dissolved-phase concentrations in groundwater often depends on the ability to flush water through the contaminated aquifer. Back diffusion of contaminant mass from low-permeability lenses, interbedded layers, and porous bedrock, as well as the partitioning of contaminant mass onto organic matter or clay particles, results in a need to substantially increase the number of pore volumes of contaminated water moved through the target treatment area. The ability of extraction to induce the flow is well documented but is relatively slow. In addition, the use of extraction alone can diminish the saturated thickness of an unconfined aquifer, potentially stranding contamination in the recently dewatered aquifer material. This material can release more dissolved contamination if extraction is terminated and water levels rebound; this may slowly leach contaminants to the water table due to infiltration.

Gradients, and therefore flux, can be increased by pairing extraction and injection. This can significantly decrease time to reach a cleanup goal, particularly where the aquifer is permeable with only minor low-permeability layers and lenses. Properly configured extraction and injection can induce flow through materials that have lower, but still modest, permeability that may otherwise be dominated by contaminant diffusion. Injection can also prevent lateral and downgradient migration of the plume. Section 3.3.2.2 discusses the evaluation of existing recirculation systems. Optimization analyses for extraction-only systems should consider recommendations for the integration of injection, which normally use extracted water that has been treated. Note that the injection of the treated water can offset or reduce costs to less than those commonly associated with discharge to POTW and can conserve groundwater resources. These strategies are discussed further in Section 6. Options for discharge of treated water are discussed in guidance from the USEPA ( USEPA 2007[P6MR8IXF] USEPA. 2007. “Options for Discharging Treated Water from Pump and Treat Systems.” U.S. Environmental Protection Agency, Office of Solid Waste and Emergency Response. https://semspub.epa.gov/work/HQ/176384.pdf. ).

Options for the arrangement of paired injection and extraction wells include extraction wells along the axis of the plume with injection wells on the periphery of the plume and extraction well transects perpendicular to the axis of the plume with injection well transects just downgradient of the extraction wells. The former arrangement is effective for collapsing the plume toward the axis, and the latter will potentially segment the plume and cause each segment to eventually shrink. Orientation of the flow from injection to extraction across the primary orientation of permeable sand zones and lenses may increase flushing of less permeable materials ( Suthersan et al. 2015[LFY6KMX6] Suthersan, Suthan, Eric Killenbeck, Scott Potter, Craig Divine, and Mike LeFrancois. 2015. “Resurgence of Pump and Treat Solutions: Directed Groundwater Recirculation.” Groundwater Monitoring & Remediation 35 (2/Spring 2015): 23–29. ). Injection wells may experience scaling and fouling issues in some settings that limit their capacity over time, so a higher number of injection wells than extraction wells are typically chosen in design; a ratio of 2:1 is not uncommon.

The use of injection wells to deliver treated water to the subsurface may require an injection permit (e.g., an underground injection control permit), depending on the circumstances. The requirements should be researched and provided with optimization recommendations. At CERCLA sites, the requirement may only be to meet the substantive, and not administrative, requirements for such permits.

4.3.1.3 Modeling Optimization

Groundwater models can be used to explore alternative extraction and injection locations and flow rates to meet project goals and minimize costs or time. Modelers can use professional judgment to iteratively run simulations of the response of the plume to the pumping/injection alternatives to converge on a good solution, and this has been the classic approach to the use of modeling for design of these systems. Additional computer tools that automate the process of exploring combinations of locations and flow rates to meet goals most efficiently, subject to defined constraints, have been developed. These tools work in conjunction with the groundwater models to search a wide solution space to find near-optimum combinations. They use search tools to select the combinations of locations and rates based on concepts from biology, metallurgy, and economics to avoid settling on “good” solutions (“local optimum”) and missing a possible better one (near “global optimum”). Demonstration projects sponsored by the USEPA ( USEPA 1999[REGMRV2E] USEPA. 1999. Hydraulic Optimization Demonstration for Groundwater Pump-and-Treat Systems. US EPA. https://www.epa.gov/remedytech/hydraulic-optimization-demonstration-groundwater-pump-and-treat-systems. ) and the Department of Defense ( Becker et al. 2006[5I6D7TBL] Becker, D.J., B. Minsker, R. Greenwald, Y. Zhang, K. Harre, K. Yager, C. Zheng, and R. Peralta. 2006. “Reducing Long-Term Remedial Costs by Transport Modeling Optimization.” U.S. Navy Research - Groundwater v. 44, n. 6: 864–75. https://digitalcommons.unl.edu/usnavyresearch/23?utm_source=digitalcommons.unl.edu%2Fusnavyresearch%2F23&utm_medium=PDF&utm_campaign=PDFCoverPages. ) have demonstrated the advantages of these automated tools relative to “trial and error” professional judgment-driven optimization. These tools can be applied during design or during optimization of existing systems, provided a suitable and accepted groundwater model exists for the site. Examples of publicly available versions of optimization codes include MODFLOW GWM (flow only), SOMOS, and modular groundwater optimizer. More detail on the use of modeling in optimization of P&T systems is provided in Appendix A.

4.3.1.4 Appropriate Extraction Well Design

|

P&T system optimization will be most successful if the extraction and injection wells are

|

A determination should be made early in the process of extraction well evaluation regarding whether the wells can be preserved at all or must be replaced (see Section 3.3). If the functionality of the extraction wells is questionable, another remedial action may need to be considered and possibly recommended. Assuming that a P&T remedy is still the preferred means of site cleanup, then it is important to determine the steps forward to improve the well performance. The choice then becomes whether to try to make the wells functional (even though they were poorly designed) or to replace them. Other performance issues may arise with extraction wells, including entrainment of formation solids or filter pack, mineral scaling or biofouling, improper pump selection and piping design, and adequacy of the controls. Proper extraction well design is outlined in many publications ( Driscoll 1987[SX2VX2GC] Driscoll, F.G. 1987. Groundwater and Wells. Second. Johnson Division, St. Paul, Minneapolis, MN. https://www.nrc.gov/docs/ML1423/ML14237A631.pdf. ).

If the extraction wells are poorly located in relation to the contaminant plume, the functionality of the extraction wells becomes irrelevant. This condition would only be determined from subsequent investigatory work and would likely result in the abandonment of the existing extraction wells and their replacement in more appropriate locations to prevent further expansion of the plume while removing it from the aquifer. Most of the COC mass typically migrates through a relatively narrow portion of the aquifer. Therefore, for effective extraction of the impacted groundwater, the screens of any recommended new extraction wells should be located such that their hydraulic capture zone directly targets the desired zone of the contaminant mass.

An effectively designed monitoring-well network must be part of the P&T system to evaluate its effectiveness through time. Monitoring of water levels and chemical trends through time provide data for evaluating that the extraction wells are functioning as designed. A contaminant plume can bypass the extraction wells for several reasons, and the monitoring wells should be placed appropriately to detect such bypass.

One reason for bypass could be that the aquifer has higher permeability than expected, and the extraction wells may not be able to create an adequate capture zone at the current pumping rates. Where the specific capacity of the well allows it, all that may need to be recommended is replacement of the existing pump with a higher capacity pump. Alternatively, if the well is equipped with a properly sized variable-frequency drive (VFD) pump, increasing the motor speed to increase the flow rate could readily be done. If the piping to the well or the treatment system limits the flow from the well, replacement of the piping with piping with a lower head loss should be recommended. If the pumping rates cannot be increased to attain hydraulic and chemical capture despite these actions or any well rehabilitation efforts, then it is likely that a recommendation for additional extraction well(s) would be necessary to achieve this goal.

Conversely, if the aquifer has low permeability, then increasing the pumping rates at individual wells is not feasible due to the hydraulic limitations of the formation. Such an extraction well may have been designed with a larger-slot screen size that would not be appropriate for the finer-grained sediments that accompany lower permeability aquifers, and this may result in solids entrainment. Capture of groundwater contamination in such an aquifer would require a recommendation for more extraction wells that would be spaced closer together and pumping at lower rates to achieve and maintain capture. The new extraction wells should be designed for the lower permeability aquifer. Again, the monitoring-well network must be able to assist in determining such conditions.

Improper extraction well installation can also impact the functionality of the well. Allowing grout to invade the well screen and gravel pack can significantly reduce its effectiveness. This can occur if the bentonite plug is too small, was not adequately hydrated before grouting, or is absent or the well is developed before the grout has had time to set up, which draws the grout down into the gravel pack and well screen. It may be necessary to recommend abandonment of such a well based on how badly it has been compromised.

4.3.1.5 Well Damage

Extraction wells create a zone of high-velocity, concentrated flow immediately outside the well screen. This has the potential to mobilize the fines forming the aquifer matrix. If the extraction well was not properly designed for a finer-grained formation, was not properly developed, or both, there can be a high potential for mobilizing and drawing these fine-grained sediments (silts and very fine sands) into the well during operation. One option to remedy this is to redevelop the well to remove the fines in the filter pack and surrounding formation. Alternatively, if the well was not properly designed, it can be replaced or slip-lined with a smaller well screen of proper dimensions. This last option may not resolve the problems encountered since the screen slot size and filter pack must both be designed to match the formation.

Fines can also be drawn into an extraction well if the screen begins to degrade and is no longer capable of restraining the formation materials from entering the well. This can occur if the well is constructed of dissimilar metals that cause a galvanic reaction to occur that corrodes or disintegrates those adjacent metals over time. Rehabilitation with strong acids can also degrade the screen over time as the screens are eaten away during subsequent rehabilitation efforts.

Twisting or pulling the screen as tools are removed from the borehole during construction can damage the screen and allow it to pump significant amounts of sediment through the pump and into the transmission lines. The sediments can then enter the well, which results in a variety of issues that negatively impact well performance, such as plugging of the sand pack, accumulation of sediment in the well (and possibly the conveyance piping), or excessive wear of the mechanical portion of the system (e.g., pump failures). If an extraction well is damaged in this way, it may need to be replaced, depending on the significance of the damage. It may be necessary to perform well sounding and video well inspection, which are useful methods of identifying the causes of sediment accumulation. Contingent actions based on these investigations may be to slip-line the well if there is damage to one section or to abandon the existing well and replace it with an appropriately designed extraction well. Such actions should be conducted in accordance with principles such as those outlined in Groundwater and Wells ( Sterrett 2007[NE7FX9SE] Sterrett, Robert J. 2007. Groundwater & Wells. New Brighton, MN: Johnson Screens. ). An inspection video recorded right after installation of the extraction well is a good way to ensure its future viability. It may be possible to take immediate actions to correct any identified issues while staff and equipment are still in the field.

4.3.1.6 Extraction and Injection Well Rehabilitation

If it is determined that an extraction well can be salvaged and not abandoned, appropriate actions can be tailored based on the previously collected diagnostic information (see Section 4.3.1.4). An extraction well that has become fouled with minerals or biomass must be cleaned before attempting to put it back into service. This is typically accomplished through extraction well rehabilitation. Optimization recommendations often address well rehabilitation, and more detail regarding potential recommendations are provided below and are based on guidance in USACE document EP1110-1-27 ( USACE 2000[LM6QTXA7] USACE. 2000. “Operation and Maintenance of Extraction and Injection Wells at HTRW Sites.” EP1110-1-27, January 27, 2000. ) and training from the U.S. Department of the Navy on rehabilitation and maintenance of P&T systems.

There are several ways to rehabilitate an extraction well once it has begun to degrade. Determining which method to use depends on the fouling issues present and their extent (Table 4‑1). Collecting additional data ahead of any rehabilitation activities can improve the effectiveness of the actions taken. Groundwater samples can be taken from the extraction wells to evaluate the biological activity in the well. This is best performed after the pump has been removed from the well to obtain samples that are more representative than those diluted by operating the extraction well. Simple biological activity reaction tests are useful for this evaluation, and other tests may also be appropriate. Downhole video logging can provide a much better understanding of conditions in the extraction well screen both before and after well cleanup actions.

Table 4‑1. Well rehabilitation techniques

|

Rehabilitation Techniques/Aids |

Extraction Wells |

Injection Wells |

Additional Considerations |

| Video Logging | Yes, especially before starting any rehabilitation work. Helps focus rehabilitation efforts on the root causes. | May be useful to observe the main issues of reduced permeability, but not in the vadose zone. | The water must be of sufficient clarity so that well features can be easily observed. |

| Mechanical Surging/Surge Block | Yes. Loosens and removes mineral and biological fouling. | Yes. Loosens and removes fouling debris, but not within the vadose zone. | Additional benefits realized when combined with chemical treatment. |

| Air Development | Yes, but best when using a “J-tube” to prevent air from entering the formation. | Yes, but only in the saturated zone. | Best when used in combination with a surge block. |

| Chemical Treatment | Yes. Helps dissolve mineral incrustation and kill off biomass. Can include biocides and dispersing agents. Adding heat improves effectiveness, especially for biological activity. | Yes. Helps dissolve mineral incrustation and (to a lesser extent) biological activity, and is also effective for any biomass present. Can include biocides and dispersing agents. Can also add heat. | Best used when combined with mechanical surging and hydraulic jetting and in combination with dispersing agents and heat. |

| Hydraulic Jetting | Yes. Very effective at physically breaking up mineral and biological fouling on the screen and within the gravel pack and surrounding formation. Should be accompanied by sediment removal right afterward. | Yes. Very effective at physically breaking up mineral and biological fouling on the screen and within the gravel pack and surrounding formation. Effective in the vadose zone. Should be accompanied by sediment removal right afterward. | Additional benefits realized when combined with chemical treatment. Can also add heat for biological destruction. |

| Hydraulic Fracturing (Fracking) | Yes, for lower permeability formations. | No. Injection wells would not be installed into finer-grained formations. There would be little success of water return to or circulation through the aquifer. | Check local regulations prior to planning to frack a water well to ensure the work is approvable. |

| Installing Adjacent Rehabilitation Wells | Yes. Helps with treating the area surrounding an extraction well; provides a broader treatment area. Used with chemical treatment. | Not likely. Would not necessarily be as helpful, especially if they are installed above the water table. | Circulating the chemicals between the rehabilitation wells and extraction wells treats the area between these wells. |

Extraction well screens are rehabilitated through mechanical and/or chemical means. Mechanical methods include the operation of a surge block, using a jetting tool, some form of air development, backwashing, and over pumping ( Driscoll 1987[SX2VX2GC] Driscoll, F.G. 1987. Groundwater and Wells. Second. Johnson Division, St. Paul, Minneapolis, MN. https://www.nrc.gov/docs/ML1423/ML14237A631.pdf. ). The first three are the most often used and most effective methods. Chemical well cleaning can involve the use of one or a combination of various acids, dispersing agents, biocides (chorine, sodium hypochlorite, chlorine dioxide gas, bromine, etc.) ( USEPA 2005[CMLMGX4C] USEPA. 2005. “A Review of Biofouling Controls for Enhanced In Situ Bioremediation of Groundwater, U.S.” EPA, October. https://clu-in.org/download/contaminantfocus/dnapl/treatment_technologies/er-0429-whtpaper.pdf. ), or off-the-shelf commercial products that may perform several chemical functions. Often, well rehabilitation involves a combination of these methodologies and may include heating the acid mixture to facilitate the reduction of active biomass within the well screen and surrounding gravel pack and formation ( USEPA 2005[CMLMGX4C] USEPA. 2005. “A Review of Biofouling Controls for Enhanced In Situ Bioremediation of Groundwater, U.S.” EPA, October. https://clu-in.org/download/contaminantfocus/dnapl/treatment_technologies/er-0429-whtpaper.pdf. ).

Rehabilitation should return the effectiveness of extraction wells with fouling conditions. If this work is not effective, the extraction wells will likely have to be replaced. It would then be prudent to develop a preventative maintenance program that periodically removes built-up incrustation and biofouling from the well screen and surrounding gravel pack and formation between rehabilitation events.

After a well is rehabilitated and is functioning within design specifications, the specific capacity should be measured along with the aquifer’s hydraulic characteristics to develop a baseline of appropriate functionality. The specific capacity can be measured to observe decreases over time. The preventative maintenance would then be employed once particular lower pumping rates, pumping water levels, or specific capacity values are reached. The preventative maintenance program should incorporate these efficiency observations and set criteria that trigger procedures to keep the extraction wells highly functioning throughout their lifespan.

At some sites, it may be necessary to improve the permeability of the formation surrounding the well screen instead of improving the effectiveness of the well screen alone. If the geology of the site consists primarily of finer-grained sediments, then producing sufficient water to achieve the remedy goals may be problematic.

This situation may be overcome through hydraulic fracturing or hydrofracking along the length of the well screen to expand fractures out from the well into the finer-grained formation. In this process, a fluid, normally water, is injected into the formation under high pressure to induce fractures. Most often, a proppant is used to keep those fractures open once the water pressure is dropped and the water recedes from the fractures. The proppant consists mainly of fine-grained, well-rounded sand. Once this process is complete, the formation surrounding the extraction well is able to produce water more effectively. It should be noted, however, that even improving the permeability around the extraction wells may not be sufficient for resolving the initial problems of installing extraction wells into a low-permeability formation.

Preventative maintenance may consist of several actions. It can consist of redevelopment using a surge block or the introduction of chemicals to dissolve and destroy mineral and biomass accumulation within and around the well screen. Full rehabilitation would typically include both mechanical and chemical treatments to achieve the most effective removal of foreign materials, whereas preventative maintenance may rely on one method or the other to improve the functionality of the extraction wells. This maintenance is typically easier to perform on a routine basis, but the effects last for a shorter period of time.

Eventually, a major rehabilitation effort will again be needed to achieve conditions closer to the baseline data established after initial well installation or the initial thorough well cleaning. The timing of this rehabilitation depends on how effective the preventative maintenance activities are at keeping the wells functioning effectively over time and how quickly the extraction well begins to foul.

To overcome a poorly designed extraction well and to enhance the preventative maintenance or rehabilitation, additional monitoring or treatment wells can be installed in close proximity to each extraction well (5 to 10 feet away). These wells would be used to help treat the area around the extraction well screen more effectively by allowing the introduction of chemicals that can be drawn through the aquifer into the extraction well. The chemicals are introduced into these treatment wells, drawn into the extraction well through the aquifer via pumping, and then more chemicals are added into the extraction well for a more thorough cleaning of the aquifer material along with the well screen. Additionally, the extracted water and chemicals can be recirculated via the treatment wells for a more thorough cleaning of the aquifer material between the wells.

Placing any of these chemicals into the extraction or injection well is an additional method of removing these fouling materials from the well screen and surrounding formation. However, simply introducing these chemicals into an extraction well will have a limited effect until and unless these chemicals are either reintroduced to regain original strength or surged or jetted to place active chemical mixtures in contact with untreated minerals or biomass. Left alone, the chemicals work on the foreign substances until their strength is spent; at that point a dead zone of spent chemicals develops between active chemicals and intact minerals or biomass. Surging or otherwise mixing these materials so they contact the intended substance again is necessary for the successful treatment and removal of these substances.

Surging with concurrent air development has been used effectively for many years ( Driscoll 1987[SX2VX2GC] Driscoll, F.G. 1987. Groundwater and Wells. Second. Johnson Division, St. Paul, Minneapolis, MN. https://www.nrc.gov/docs/ML1423/ML14237A631.pdf. ). The surge block may consist of two sets of surge blocks with rubber disks that are separated by a perforated pipe between them. Inside the pipe is a “J-tube” air development tool. An air line enters the perforated pipe and then is bent back up toward the surface to make a “J” shape (Figure 4‑2). The surge block is raised and lowered starting at the top of the well screen. At any point during this development, the air is sent down the pipe string, and any sediment, minerals, or biomass dislodged by the surge blocks are removed immediately and sent to the surface. One section of screen is worked at a time until the entire screen has been cleaned.

Source: Photograph provided by Charles Graff. Used with permission.

Surging can also be performed while adding acid or an acid/chemical blend through a similar perforated pipe between two surge blocks. This combination action pushes the chemical mixture out into the formation while thoroughly mixing the chemicals between the inside of the screen to the farthest extents of the formation. After the chemicals are mixed into the screen and formation, they are allowed to work in the fouling materials for a period of time. This is typically followed by surging to remove the chemicals and the fouling materials from the screen and surrounding formation. Using a dispersing agent will keep these materials in solution during the surging and removal process; it is like using soap to wash something versus only using water.

Jetting with water is another effective means by which to break up fouling materials and remove them from the well. Jetting with water is preferred rather than using air on environmental sites for a few reasons. Air can potentially become entrapped in some formations, creating air locking, which serves to decrease the formation’s permeability while also altering the geochemistry of that zone around the extraction well. Water will break up the fouling material effectively without creating any deleterious effects. Jetting is most effective with screens that have a high open area, such as continuous slot screens. Water jetting can also use chemical mixtures or straight acids, as in the previous methods described above. These further increase the effectiveness of the jetting process. Jetting on polyvinyl chloride (PVC) or less robust screens should be evaluated carefully. The pressure could exceed the screen’s ability to hold up during the process. Jetting pressures can range from a few hundred to a few thousand pounds per square inch. Jetting these types of wells could be helpful or harmful, depending on how this process is used and the construction of these wells. Jetting an extraction well is a quick process and should be accompanied by sediment removal immediately afterward.

Air development by itself is effective but is best used in combination with another form of mechanical well redevelopment or rehabilitation, as with a surge block noted above. There are several drawbacks to traditional air development. Air quality near the well can be compromised by releasing hazardous volatile compounds into the breathing zone. Displacing large amounts of contaminated water onto the surface is another health and safety issue if it cannot be contained. Traditional air development is typically a vigorous process that can send air-entrained water far above the wellhead. Air surging is not commonly used on environmental sites for these reasons.

It is important to note that some acids can have negative effects on an extraction well after the rehabilitation process is finished. Some hydrochloric acids are buffered, but some are not and can eat away at the well screen and casing material during the well cleaning process, which can significantly reduce the lifespan of an extraction well over time. Phosphoric acid can effectively remove mineral or biomass from an extraction well, but any acid left behind (phosphorus) becomes food for bacteria with the effect that they soon flourish around the well screen and create a condition worse than what existed before the well rehabilitation process began.

Fewer problems are associated with treating water injection wells, but these wells must still be monitored to ensure they are allowing groundwater to be returned to the aquifer in an efficient manner. The change in the geochemistry of the groundwater after its treatment can cause fouling issues in an injection well that reduces its connection to the aquifer. The treated groundwater is more oxygenated than when it was removed from the aquifer, and this oxygenation can cause soluble metals present in the groundwater to precipitate as they leave the well screen. For these reasons, injection wells must be closely monitored for plugging, and these issues should be considered during planning to evaluate whether to install injection wells or not.

Over time, this process can progressively foul the well screen and surrounding formation, significantly decreasing its permeability and its ability to accept injected groundwater. Left for too long, this condition may not be treatable, and the injection well would have to be abandoned and a new location chosen for further injection. At some sites this may not be feasible for any number of reasons, so proper monitoring and maintenance are necessary to avoid such situations.

Injection wells can also lose their capacity to accept water due to minute amounts of fine sediment being pumped from the extraction wells ( Driscoll 1987[SX2VX2GC] Driscoll, F.G. 1987. Groundwater and Wells. Second. Johnson Division, St. Paul, Minneapolis, MN. https://www.nrc.gov/docs/ML1423/ML14237A631.pdf. ). This sediment is rarely noticed as it is pumped from the extraction well but can cause significant problems in the receiving well over time. Similarly, small amounts of air contained in the returning water can become entrained in the formation around the well screen and effectively plug it off.

Before an injection well becomes problematic, preventative maintenance and rehabilitation similar to that for an extraction well can improve its ability to receive treated groundwater again. This would include mechanical and chemical means similar to cleaning out an extraction well. Once the rehabilitation is complete, the injection well can again receive water effectively.

4.3.1.7 Well Abandonment

Recommendations should be made to properly abandon (decommission) any unnecessary or nonfunctional monitoring, extraction, or injection wells. These wells may represent a potential for vertical contaminant migration or contamination from near-surface sources. The abandonment and associated documentation would typically be required to follow state requirements for such work.

4.3.2 Monitoring Optimization

The optimization evaluation should evaluate the current monitoring program. The goal of these recommendations should be to identify the data that need to be collected to support decisions in a timely manner without unnecessary redundancy or data gaps and should consider the apparent variability in past sampling results. The USEPA guidance ( USEPA 2005[274XPBTQ] USEPA. 2005. “Roadmap to Long-Term Monitoring Optimization.” https://www.epa.gov/sites/default/files/2015-08/documents/roadmap_ltmo_542-r-05-003.pdf. ) on the subject may be very helpful to the optimization team, and the U.S. Navy has comprehensive guidance ( NAVFAC 2010[SWFQZYK4] NAVFAC. 2010. “Department of the Navy Guidance for Planning and Optimizing Monitoring Strategies.” U.S. Department of Defense, Department of the Navy. https://frtr.gov/matrix/documents/Monitored-Natural-Attenuation/2010-Guidance-for-Planning-and-Optimization-of-Remedial-Strategies.pdf. ) as well. The primary considerations for optimization are as follows:

- the frequency of sampling

- the location of sampling (the monitoring network)

- the methods of sampling

- the analytical program

- the management and reporting of data

The optimization recommendations normally focus on the groundwater monitoring program, but the recommendations can also extend to the process for monitoring the aboveground treatment system. In this case, the same considerations apply, but recommendations often address the frequency of sampling and analysis of the effluent (water and air) and at key points in the treatment stream for compliance and process control.

Optimization can be conducted qualitatively using expert professional judgment. Key considerations for evaluating the frequency and locations of sampling are the rate at which the concentrations are changing, the proximity to potential receptors, the rates of plume migration in various directions, and the goals of the monitoring (monitoring the plume boundaries, assessing cleanup progress, or early warning of potential impacts to receptors).

The analysis can also be conducted (semi) quantitatively. This has advantages where there are many sampling points and contaminants, where clear decision logic would build stakeholder trust in the results (relative to subjective judgment), and where data are readily available in electronic form (i.e., a database). Several public-domain computer-based tools are available to facilitate the quantitative analysis, such as Monitoring and Remediation Optimization Software (MAROS) and the Groundwater Spatiotemporal Data Analysis Tool (GWSDAT). Commercial tools include, for example, SampleOptimizer. The U.S. Air Force developed two powerful monitoring optimization tools: Geostatistical Temporal/Spatial (GTS) Optimization software version 1.1 (an update is in development at the time of this guidance) and the Three-Tiered Monitoring Optimization Tool (3TMO). Appendix A has additional information on relevant software, and a useful comparison of capabilities and requirements for these tools is provided in a table on the USEPA Clu-In page. Refer to the Federal Remediation Technology Roundtable monitoring optimization page, as well.

The appropriate frequency of sampling groundwater depends on the following factors:

- The variability of the results over time—the less predictable the results of sampling, the more frequent the sampling that is recommended.

- The degree of risk of exposure—if the plume is far from a receptor (well or surface-water discharge points), the less frequent the recommended sampling frequency would be.

- The time necessary to address unexpected plume migration—if the rate of plume migration is fast, there may be less time to adjust the remedy to address the change, so more frequent sampling maximizes the available time to react.

- The degree of correlation over time—samples taken at shorter time intervals will generally be more similar than samples separated by longer time intervals, so samples taken at shorter time intervals are correlated and not fully independent; assessing the time-correlation relationship can optimize the frequency.

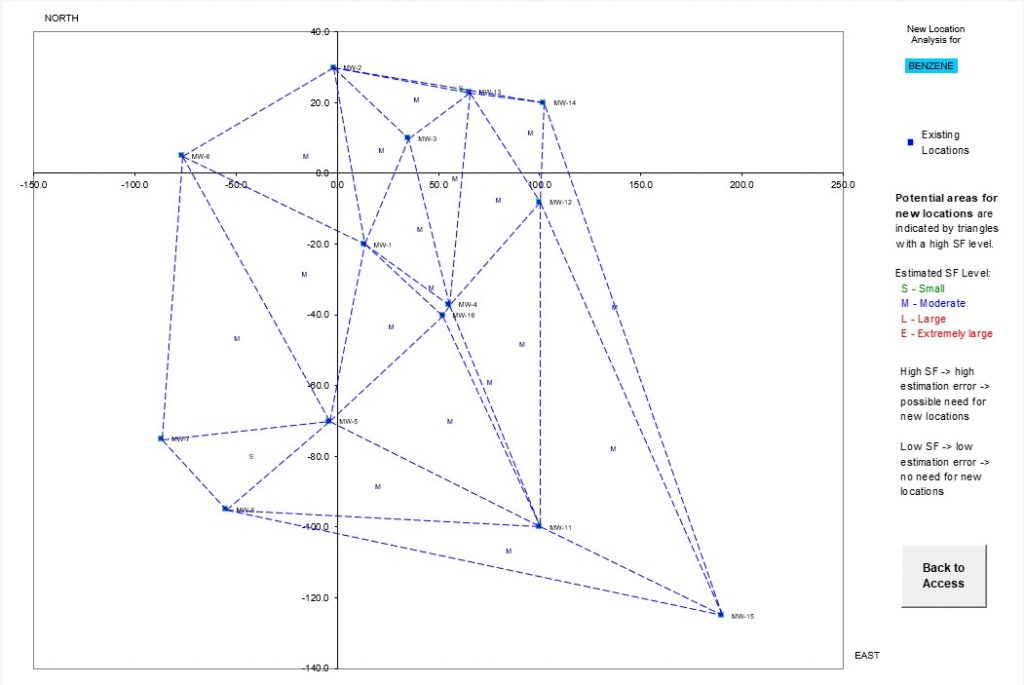

The distribution of monitoring wells in remediation is usually inherited from the characterization phase where the wells were usually installed for other purposes. Reductions in monitoring locations are often appropriate. In other cases, there are important areas that are unmonitored. Optimization of the monitoring network should consider the typical decisions to be made and assess the progress of remediation and verify plume boundaries to prevent exposures. The spatial correlation between monitoring wells (the geostatistical range—see ITRC guidance on Geostatistical Remediation Optimization) should be minimized while avoiding data gaps. Data gaps can be identified by quantifying uncertainty in the values interpolated at a point based on surrounding measurements (e.g., well sufficiency as shown in Figure 4‑3). The analysis can also consider hydrogeology and likely preferential pathways and target those locations, especially for monitoring the plume boundaries and potential plume migration.

Source: David Becker. Used with permission.

In many cases, labor- and time-intensive methods of sampling can be replaced by alternative methods that provide high-quality data with lower sampling costs. These methods can include passive and no-purge sampling methods. See the ITRC guidance ( ITRC 2022[Z89VS42J] ITRC. 2022. “Diffusion/Passive Samplers.” The Interstate Technology & Regulatory Council. 2022. https://itrcweb.org/teams/projects/diffusion-passive-samplers. ) on the use of these sampling methods. In addition, focusing the analytical program only on key contaminants (and excluding classes of compounds that have not been nor would be expected to be found at the site) and using cost-effective analytical methods that meet the data quality objectives can make the program most cost-effective.

In most cases, analytical data are delivered in electronic form and should be managed in the electronic format appropriate for the site complexity. Geographic information systems can make the results much more usable to the project team and simplify the optimization efforts. Reporting frequency should be based on the frequency of sampling and decision-making, and report detail should meet the needs of decision-makers. Streamlining reporting can be an effective way to improve cost-effectiveness. ITRC has developed guidance on Environmental Data Management Best Practices that is very relevant to this topic.

Note that monitoring wells no longer necessary for sampling may still yield valuable information on the hydraulic conditions. Recommendations for retaining these wells for water level measurements should be considered. The frequency of piezometric monitoring can also be optimized. Though the cost of piezometric monitoring is low compared to sampling, there are still costs for conducting the measurements. If there is a long history of piezometric measurements and any seasonal changes are well understood, recommendations for reductions of the frequency of water level measurements from quarterly to semiannual or annual may be appropriate. If substantial changes to the extraction and/or injection rates and locations are recommended, more frequent water level measurement rounds may be appropriate to recommend.

Recommendations related to assuring the resilience of the monitoring network to expected changes in climate may be appropriate. See Section 6 for more details.

Recommendations to optimize the monitoring necessary to efficiently run treatment processes should be made. The optimization considerations (e.g., adjustment of frequency, location, and reporting) for the collection of data on flow, concentration, pressures, and parameters such as pH and temperature may be similar to those for the subsurface data.

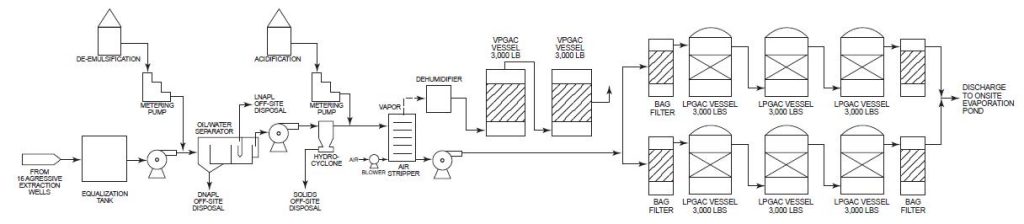

4.3.3 Treatment System Optimization

The optimization evaluation recommendations should address the aboveground treatment components. This would include the piping, process water pumps and associated motors, process controls, treatment components (e.g., air stripper, activated carbon, chemical feed systems, solids separation, etc.; Figure 4‑4 shows a typical system), chemical dosages, and treated water discharge options. The recommendations may range from adjustments to existing equipment or chemical dosages, to removal or replacements of specific treatment steps, to replacement of the entire treatment train. These typical recommendations are discussed below. Options for treatment for various contaminants are summarized in the Federal Remediation Technologies Roundtable Treatment Technologies Screening Matrix.

As summarized in the ITRC Fact Sheet on Above-Ground Treatment Technologies prepared by the ITRC Remediation Process Optimization team in 2006, the optimization recommendations related to aboveground treatment address the following factors:

- improvements in treatment performance

- reductions in costs for labor, materials, utilities, consumables, and maintenance

- elimination of unnecessary or redundant treatment processes

- improvements in reliability and safety

Some of the common recommendations are described in subsequent sections.

4.3.3.1 Modification to Operational Parameters

Based on the performance evaluation, the optimization team should consider what changes, if any, are appropriate to operational status for both the aboveground and subsurface components. Recommendations for the rate of chemical addition to alter pH, reduce or oxidize contaminants (e.g., permanganate or peroxide addition), or promote or inhibit coagulation (e.g., polymer or sequestrants) can be made to improve the treatment performance or reduce costs. The dosages of some additives may not have been changed from design levels despite changes in influent characteristics. Routine and periodic reevaluation of the necessary levels of additive concentrations, target pH, etc. should be done and may require a recommendation for bench-scale testing.

For systems including carbon adsorption as a treatment process, the recommendations may address the basis for changing the carbon media. Where carbon vessels are arranged in a “lead-lag” pair, the change out of the carbon in the lead vessel based on an initial detection may leave sorptive capacity unused if the breakthrough front is not particularly steep; this depends on the types of contaminants being treated. Deferring change out until concentrations leaving the lead vessel are some larger fraction of the influent concentrations can reduce carbon usage and costs. Adding a separate and specific treatment for a specific contaminant that is poorly sorbed (e.g., permanganate-impregnated carbon for treatment of vinyl chloride in air stripper off-gas) may allow greater loading of other contaminants on the carbon.

If air stripping is being used for contaminant removal, it may be possible to adjust air–water ratios to reduce electrical use by reducing blower speed or replacing the blower. Such adjustments should be made in coordination with the stripper manufacturer because minimum air flow must be met.

If ultraviolet-oxidation (UV-Ox) is a treatment process, the appropriate ultraviolet (UV) lamps may be different from those in design given changes in the mix and concentrations of contaminants. Recommendations could be made to replace current bulbs with other less energy-intensive bulbs. Some UV-Ox systems have the feature that allows the energy output of each bulb to be adjusted or for some bulbs to be turned off. This allows for routine periodic optimization of UV output as influent parameters change. More optimization considerations are provided in the ITRC fact sheet Above-Ground Treatment Technologies.

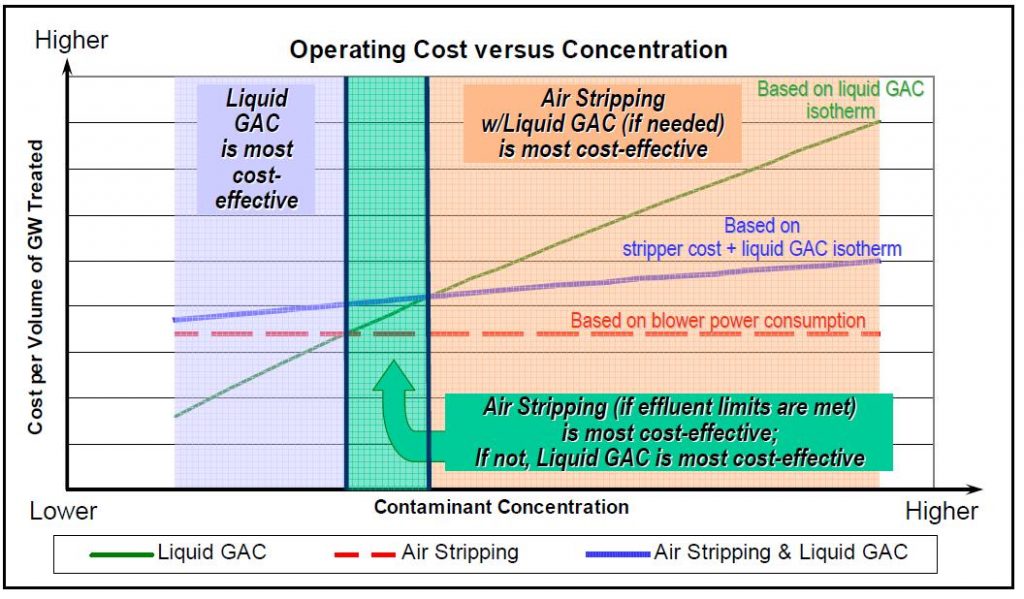

4.3.3.2 Modification to, Removal of, or Replacement of Treatment Components

In some cases, the optimization team may recommend the replacement or removal of a specific piece of equipment or a process in a treatment train to improve the performance, reliability, and cost-effectiveness of the system. Common recommendations would include the replacement of thermal treatment of off-gas from an air stripper with vapor-phase carbon, replacement of metals precipitation steps with the addition of a sequestrant, or replacement of an inclined plate clarifier with sand filtration and backwashing. Air stripping with carbon polishing may represent redundancy if contaminant concentrations have declined adequately such that just one of the two technologies would be adequate. Figure 4‑5 illustrates how stripping with GAC is most cost-effective at high contaminant concentrations. As concentrations decline, stripping alone may be most cost-effective. As concentrations decline even more, liquid GAC alone is most cost-effective. For these transitions, it is useful to know in advance what contaminant concentrations would trigger the transition to allow the transition to take place at the optimum time. Oil and water separation may not be necessary if separate phase removal has been adequately reduced such that sorbent clay could address any minor amounts of product. The disposal options for treatment residuals should be evaluated to explore less expensive or more sustainable alternatives. In some cases, the consolidation of multiple treatment plants at a large site may be economically justified. Note that the recommendations discussed above should consider the impacts of any recommended changes on the subsurface components that would increase concentrations or change flow rates. Again, more optimization considerations are provided in the ITRC fact sheet Above-Ground Treatment Technologies.

Source: U.S. Navy Remediation Innovation Technology Seminar Training Materials. Used with permission.

4.3.3.3 Treatment System Maintenance Recommendations

Many P&T systems were installed more than 20 years ago, and treatment components may be nearing or have exceeded their design life. The duration of P&T projects is often decades or centuries, and extensive maintenance and replacement of equipment will likely be necessary in the long run. The optimization team should make recommendations for actions needed to address maintenance, repair, and replacement issues with the aging equipment. The recommendations may address the following issues:

- modifications to inspection frequency and checklist items

- changes to the preventative maintenance practices to address recurring problems

- diagnostic procedures to assess root causes of equipment or process failures (if not immediately obvious)

- replacement of components that have exceeded their useful life, that have become obsolete, or that require frequent or expensive maintenance

- corrections of design flaws (e.g., material compatibility issues)

These actions would not necessarily require a change in the general nature and purpose of the equipment but would often involve updating the existing components. Some examples of recommendations are listed below:

- assessment of vessel corrosion

- replacement of communications cables to extraction and injection wells

- periodic inspections/testing and cleaning of all alarm conditions, sensors, and floats

- investigation into causes of pump failure

- updating of control systems to current versions (that may be more secure)

Given the number of different components and treatment processes, specific recommendations for each are not provided here. Tools for optimization offered in Appendix C provide suggestions for optimization recommendations specific to treatment processes, such as air stripping, carbon adsorption, chemical feed systems, etc.

4.3.3.4 Use of Technology/Automation

Various types of technology can be used to remotely monitor and automate operation of the P&T system. Real-time data collection and the resulting comprehensive data sets can help optimize system operation. Technology that allows for remote control of system components, automated digital data collection, and electronic transmittal of data to system operators allows for a more comprehensive evaluation of overall system performance in response to optimization changes. These monitoring systems support use of an adaptive management strategy for the P&T system and provide tools to detect subtle changes in the contaminant plume or P&T system performance. This often leads to a reduction in labor costs for site personnel as well as costs for management and reporting.

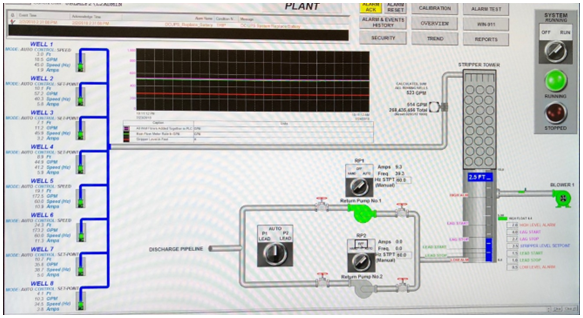

SCADA systems: The remote monitoring and control allowed by a SCADA system (Figure 4‑6) can be used to implement changes during the optimization evaluation. Well extraction rates, total system flows, fluid levels, weather conditions, system faults, and other observation parameters can be tracked remotely either intermittently or continuously. Data can be automatically recorded and used to evaluate optimization results. If specific optimization criteria are not being met, automated messages can be sent to the system operator to indicate that adjustments may be needed. SCADA system controls (Figure 4‑7) can also be set to automatically adjust pumping rates at extraction wells to maximize the system optimization. This can allow withdrawals from wells in a P&T system to focus on the desired influence for the groundwater recovery system—increasing pumping rates where desired (to improve mass removal or maximize drawdown) and decreasing pumping rates where desired (for example, to reduce plume movement in a specific area or to limit the influence of specific wells).

Source: Dave Becker. Used with permission.

Source: Dave Becker. Used with permission.

The ability to control pumping rates at individual wells can be valuable when optimizing a P&T system because it allows more control of the individual components of the groundwater recovery system. The ability to control the system remotely can reduce the time operators have to spend on site, potentially reducing labor costs and carbon footprint (i.e., fewer trips to the site by vehicle). Programming the SCADA controls to incorporate system changes recommended for optimization can be expensive, especially with legacy or obsolete systems. The costs and benefits of programming changes and possibly updating the SCADA system should be considered when planning optimization.

Data loggers and telemetry: Transducers that monitor fluid levels (pressures) or geochemical indicators can be installed to monitor field conditions during implementation of P&T optimization. Telemetry (for example, cellular or radio telemetry) can be used to allow remote monitoring of the field measurements collected. This provides a near real-time method of observing how adjustments to the P&T system completed as part of system optimization are affecting the system performance. Changes in groundwater flow directions can be interpreted from the fluid levels recorded. Changes in plume movement can be inferred from changes in the geochemical indicators. As with the use of SCADA technology, the ability to monitor subsurface conditions remotely at a defined frequency can aid decisions about the effectiveness of the optimization efforts during the early stages following implementation of the optimization. Recommendations for using these automation tools can result in labor savings and more timely and efficient reactions to system and subsurface changes.

VFD pumps: Groundwater recovery wells fitted with pumps that allow for control of the rate of groundwater extraction can provide great flexibility for managing the operation of a groundwater P&T system and prolong the lives of the pumps. Such VFD pumps provide improved control over pump operation and provide a mechanism for setting operating parameters for flow rates or water levels to be optimal for the aquifer conditions present at the well. Flow is controlled by varying the speed of the motor driving the pump rather than opening or closing a valve to change the back pressure sensed by the pump. The constriction of the valve represents an energy cost. As such, the VFD motor/pump can be more energy efficient than other types of pumps.

VFD pumps can allow for pumping rates to automatically vary upward or downward to maintain a constant water level in the pumping well. Use of these pumps can help maintain withdrawal of groundwater from a pumping well by allowing the well to continue pumping at a lower rate when water levels decline and the saturated thickness around the pumping well is not sufficient to support a higher pumping rate. The result is a well that can pump continuously rather than intermittently. In addition, VFD motor/pumps allow the extraction rates to be tailored to optimize the capture zone over time as the plume changes and integrate wells into SCADA controls. VFD can also help to extend the life of the pump motor by allowing for a “soft start,” which helps to minimize motor wear and tear over the life of the P&T system.

4.3.3.5 Conveyance System Modification/Improvement

Based on the evaluation of the hydraulic performance of the existing piping system, the optimization team may recommend changes to the maintenance practices for the piping or even the replacement of existing piping with larger diameters or different materials to reduce pressure losses (and corresponding electrical use) and to better resist corrosion or abrasion. The use of piping cleaning techniques, such as “pigging” or jetting may need to be initiated or increased to maintain flow. The addition of access wye joints for conveyance system access, periodic inspection, and cleanout activities may be necessary to facilitate insertion and removal of inspection instruments and tools used for cleaning. Chemical addition at the wellheads may be recommended to prevent scaling within the extraction system piping, or the recommendation may be made to investigate and remedy the source of solids causing piping abrasion. If the piping materials are failing due to corrosion, the replacement of the affected piping may be recommended, with consideration given to the appropriate materials for current chemical concentrations. Cathodic protection could be recommended to inhibit corrosion, as well.